Dot Peen also known as “pin marking,” is performed utilizing compressed air to move a probe that rapidly indents dot-shaped marks into a surface.

This is a process that will depress or remove small amounts of material at the site, The process is normally reserved for applications where the customer is serializing parts for long term referencing and needs to hard mark parts that may be utilized in harsh environments.

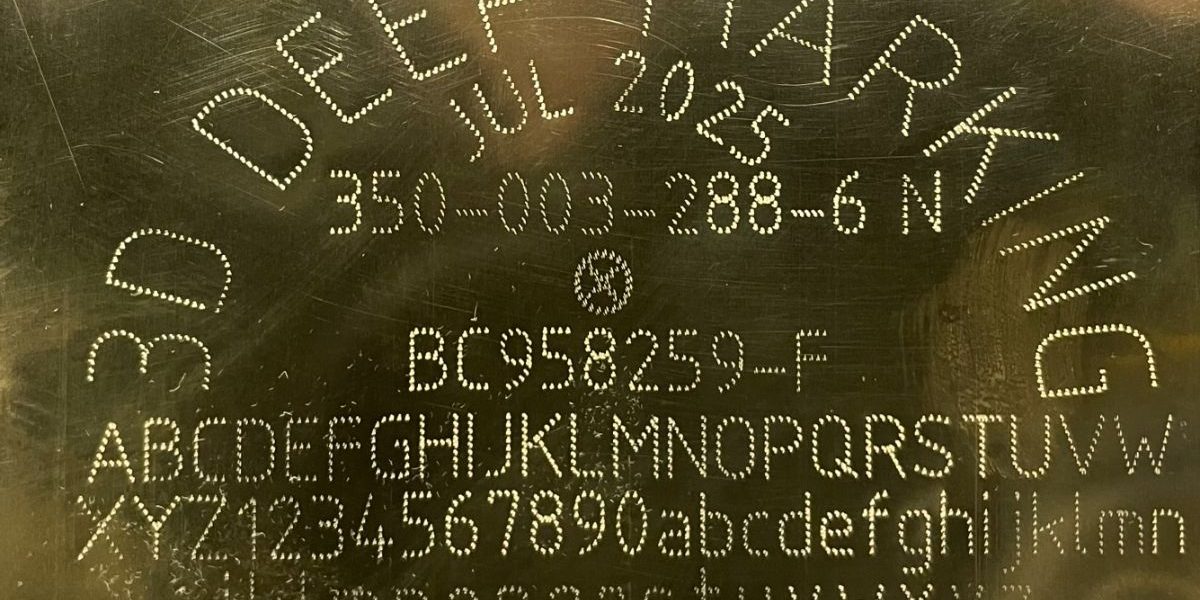

The Dot Peen machines work by using a single pin to mark materials with customer-specific information. The result is a specific dot pattern that creates deep characters (serial numbers, batch numbers, date codes, etc.), logos, and codes (Data Matrix). Dot peen marking machines can mark materials with a hardness level up to 62HRC.

You can apply permanent serial numbers, 2D Data Matrix codes, logos, Date/time stamping, Part serialization, and other identification or traceability information to a wide variety of products.

Stainless Steel, Ferrous Metals, Aluminum, Brass, Bronze, Titanium, Hardened Metals.

Contact us for more information on capabilities and a full list of materials for your project.